rectangular tnesion test specimen of thickness 8 mm|astm e8 tensile testing : chain store The specimen thickness and bend radius are shown in Figures QB-466.1, QB-466.2, and QB-466.3. Guided‐bend specimens are of five types, depending on whether the axis of the joint is . WEBMOTEL O SONHO. Delicie-se no nosso enorme Jacuzzi! Suite Cascata do Amor. MOTEL O SONHO. Banheira de Hidromassagem em Cascata com Leds no fundo. Suite Lagoa do Prazer. . Se continuar a usar este site, sem alterar suas configurações de cookies, ou clicar em "Aceitar" abaixo, concorda com a sua utilização. .

{plog:ftitle_list}

webNo poker, existem várias estratégias que os jogadores utilizam para maximizar seus ganhos e minimizar suas perdas. Uma dessas estratégias é a Block Bet ou, traduzindo à letra, .

The ASTM E8 / ASTM E8M standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break .

Bars, tubes, sheets, pin-loaded specimens, round specimens, and powdered metallurgy products are some of the many options for testing to this standard. However, the most common .The specimen thickness and bend radius are shown in Figures QB-466.1, QB-466.2, and QB-466.3. Guided‐bend specimens are of five types, depending on whether the axis of the joint is .This specimen is used for testing metallic materials in the form of sheet, plate, flat wire, strip, band, hoop, rectangles, and shapes ranging in nominal thickness from 0.005 to3⁄4in. When .Scope* 1.1 These test methods cover the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of yield strength, yield point elongation, tensile strength, elongation, and reduction of .

E8:2016 standard specifies standard plate-type test specimen is shown in Figure 3. This specimen is used for testing metallic materials in the f. rm of plate, shapes, and flat material .Purpose. To obtain the material’s stress-strain relationship. To determine the following structural properties: modulus of elasticity, yield strength, ultimate tensile strength, failure strength, and .

standard tensile testing

6.3.1 The standard sheet-type test specimen is shown in Fig. 1. This specimen is used for testing metallic materials in the form of sheet, plate, flat wire, strip, band, hoop, rectangles, and .The ASTM E8/E8M tension test is performed on metallic materials in any form at room temperature. Specifically, it determines properties of metals such as yield strength, yield point elongation, tensile strength, elongation, and reduction of .FIG. 15 Standard Tension Test Specimen for Cast Iron If D/W # 6: FS D G FS D G FS D S DG FS D S DG W D2 W 2 2 D – W 3 1 – ! ~ = 4 4 3 arcsin D 2 D – 2T W 3 arcsin D – 2T 3 =~D – 2T!2 – W2 – 2 A5 W 4 (1) where: A = exact cross .

parallel section of the test specimen. The specimens were fabricated with an abrasive waterjet cutter from sheet material. Figure 1: ASTM E8 [2] rectangular tension test specimen used for uniaxial testing (nominal dimensions in mm). 2.2. Mechanical testing equipment Figure 2 shows the testing machine and the location of DIC cameras and lighting.A specimen of ductile cast iron having a rectangular cross section of dimensions 4.8 mm×15.9 mm(3/16 in. ×5/8 in.) is deformed in tension. Using the load-elongation data shown in the following in table 1, complete problems (a) .FIG. 1 Rectangular Tension Test Specimens 6.1.2.2 Midway from the center to the surface for products over 11⁄2 in. in thickness, diameter, or distance between flats. 6.1.3 Specimen Machining—Improperly prepared test specimens often are the reason for unsatisfactory and incorrect test results. . NOTE 2—The dimension T is the thickness of .A specimen of ductile cast iron having a rectangular cross section of dimensions 4.8 mm x 15.9 mm is deformed in tension. Using the load-elongation data tabulated below, complete problems (a) through (e) a) Plot data as engineering stress versus engineering strain (Use the Excel if possible, and show the graph on a separate sheet, or copy on the bottom.)

The specimen had a rectangular cross section with original dimensions width 14.5 and thickness 4.02 mm. After fracture, these dimensions were width 9.5 and thickness 2.02 mm. Gage marks originally 50 mm apart had stretched to 82.5 mm after fracture, which occurred at a load of 1.319 kN.

FIG. 7 Pin-Loaded Tension Test Specimen with 50-mm [2-in.] Gauge Length length shall be parallel to each other and to the longitudinal axis of the specimen within 0.05 mm [0.002 in.]. . This is the case for example, when the width or thickness of a rectangular tensile test specimen is increased. X1.4.4.2 Holding the Lo/(Ao)1/2 ratio constant .The dimension of rectangular tensile test sample according to the ASTM B557M. . of hardness was obtained along with the tube thickness. The electrical conductivity of the copper tube decreased .4.3 These test methods are considered satisfactory for ac-ceptance testing of commercial shipments. The test methods have been used extensively in the trade for this purpose. 5. Apparatus 5.1 Testing MachinesÑ Machines used for tension testing shall conform to the requirements of Practices E4 . The forcesQuestion: a P9. Engineering stress-strain data from a tension test on PMMA polymer are given in the table below. The specimen had a rectangular cross section with original dimensions width 12.61 and thickness 2.92 mm. After fracture, these dimensions were the same within the repeatability of the measurement.

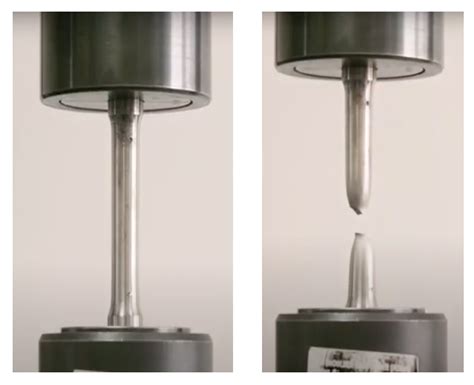

When the tension test is started and Specimen A or Specimen B is pulled, the strain is uniform along the gauge length up to the point at which the maximum force is reached and the onset of necking occurs. The stretch in each material is uniform up to this point. The force will then start to drop, as shown in the stress-strain curve below, and .A specimen of steel has a rectangular cross section 20 mm wide and 40 mm thick. an elastic modulus of 207 GPa, and a Poisson s ratio of 0.30. If this specimen is pulled in tension with a force of 60,000 N, what is the change in width f deformation is totally elastic?

Question: specimen of steel has a rectangular cross section 20 mm wide and 40 mm thick, a Young's modulus of 207 GPa, and a Poisson's ratio of 0.30. If this specimen is pulled in tension with a force of 60, 000 N, what are the changes in width and thickness? Miniaturized Tensile Test (MTT) is one of the most widely used methods of SSTT [19], which uses specimens spanning several millimeters to hundreds of microns in the smallest dimension (thickness or diameter).However, MTT faces great challenges from specimen size effects and high sensitivity to measurement errors, as well as high demands for operation .Tensile testing on a coir composite. Specimen size is not to standard (Instron). Tensile testing, also known as tension testing, [1] is a fundamental materials science and engineering test in which a sample is subjected to a controlled . The shortest gauge length for rectangular tensile specimens is 25 mm for the ASTM E8/E8M subsize specimen 6 mm wide. In this work, a scaled-down version of the subsize specimen 6 mm wide with a gauge length of 12.5 mm was tested in a commercially available universal testing frame.

Tensile tests on beech, pine and steel specimens with rectangular cross-sections, (Fig.4). The specimens had L t =300 mm of total length and a=10 mm of thickness.

In a tension test on a bar, gauge length means the length over which extension is measured. \(GL = 5.65\;\sqrt {{A_o}}\) Where A o = Initial cross-sectional area before loading. Gauge length is independent of the length of a bar, material of bar, and shape of cross-section. Calculation: Given, A o = 50 × 82.3.1. Differences of test specimen In this paper, a rectangular plate type test specimen dimensional differences is given as an example between standards. There are also differences in dimensions of other types of tensile test specimens so details can be viewed from both ISO 68921:2016 and ASTM E8:2016 standards- . Rectangular tension test .

A specimen of magnesium having a rectangular cross section of dimensions 3.2 mm times 19.1 mm (1/8 in. times 3/4 in.) is deformed in tension. Using the load-elongation data tabulated as follows, complete parts (a) through (f). Plot the data as engineering stress versus engineering strain. Compute the modulus of elasticity.1) A metal specimen having a rectangular cross section 10.8 mm x 12.5 mm is pulled in tension with a force of 34,300 N.It produces only elastic deformation. Given that the elastic modulus of this metal is 79 GPa, calculate the resulting strain.. 2) A tensile test is performed on a metal specimen, and it is found that a true plastic strain of 0.20 is produced when a true stress of .

A tension test of the dog-bone-shaped specimen was conducted using a similar apparatus for the straight specimen at a crosshead speed of 0.8 mm/min. As described above, the width of the specimen was determined to be 15 mm by JIS P8113-2006 [ 18 ]; therefore, a tension test of the specimen with the width of 15 mm was preliminarily conducted.

The following date were collected from a 20 mm diameter test specimen of a ductile cast iron (l_o = 40.00mm): After fracture, the total length was 47.42 mm and the diameter was 18.35 mm. Plot the data; A cylindrical specimen of stainless steel having a diameter of 12.8 mm and a gauge length of 50.8 mm is pulled in tension.

Question: Question 11: L w A specimen of some metal having a rectangular cross section 10.8 mm x 12.5 mm is pulled in tension with a force of 34,300 N, which produces only elastic deformation. Given that the elastic modulus of this metal is 79 GPa, calculate the resulting strain ENGG1023 Engineering Materials Experiment#2 Hardness Test 1 . 550 N.W. LeJeune Road, Miami, Florida 33126 AWS B4.0M:2000 An American National Standard Approved by American National Standards Institute July 25, 2000 Achieving a successful uniaxial tension test is greatly influenced by the shape and dimensions of the test sample. While tension tests can be adapted to various objects using customized grips, the standard practice involves testing raw materials by shaping them into “Dogbone” samples. This term describes a distinctive shape characterized by .550 N.W. LeJeune Road, Miami, FL 33126 AWS B4.0:2007 An American National Standard Approved by the American National Standards Institute May 2, 2007

astm e8 tensile testing

WEB19 de ago. de 2016 · Estás a ver as odds para o 1X2? No Placard o prémio é de 180€ .

rectangular tnesion test specimen of thickness 8 mm|astm e8 tensile testing